Goldwin Play Earth Fund PORTFOLIO INTRODUCTION

Vol.6Ambercycle

California-Based Startup Ambercycle

ー First, could you tell us about how you established Ambercycle?

Shay: I’ve always been drawn to the question of how we build a more beautiful world—one that's self-sustaining, efficient, and elegant. That curiosity led me to wonder about large-scale consumption challenges, and one that really stood out to me was the problem of "old clothing” fashion.

ー By "old clothing," you mean worn-out clothes, correct?

Shay: That's right. What happens to our clothes when we’re done wearing them, and why can’t we use old clothing to make new clothing? This would not just be sustainable, but truly circular.

ー So you wouldn't need to use new resources, but could create a cycle with what we already have.

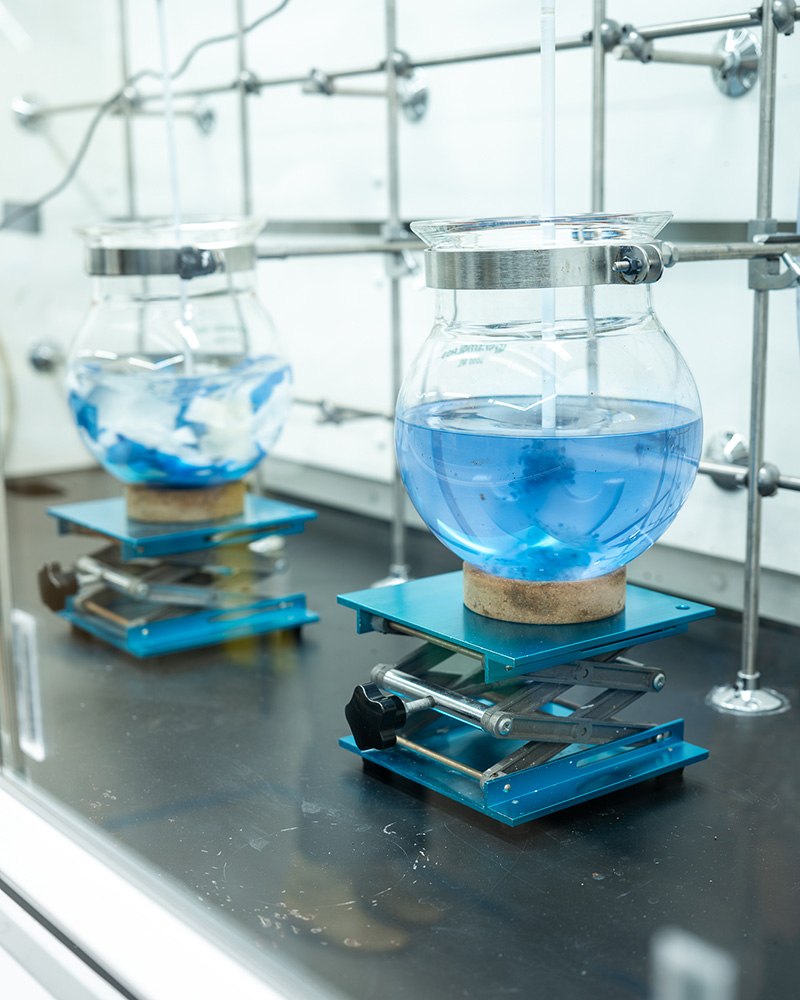

Shay: Then, While studying Biochemistry and Molecular Biology at UC Davis, my college roommate, Moby Ahmed, and I began exploring how we could apply science to solve that problem. We started Ambercycle together in our dorm room. Materials shouldn’t have to end up in landfills or incinerators. We believed there had to be a better way.

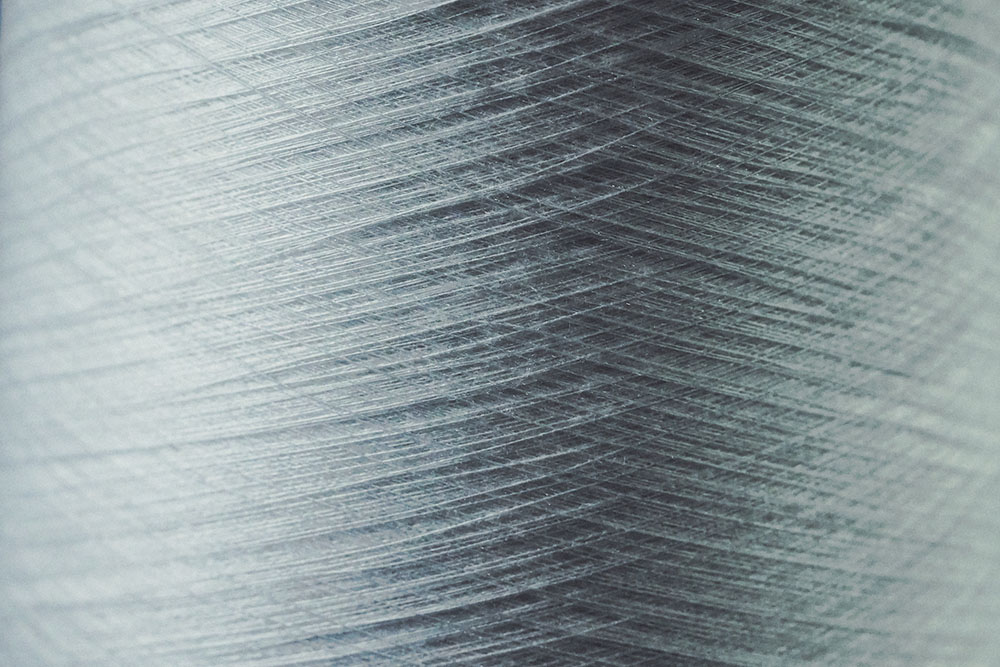

What began as an experiment in a college lab has grown into a company building the infrastructure for circularity in fashion—starting with our molecular regeneration technology, which transforms end-of-life textiles into new, high-quality material, known as cycora®.

A Challenge That Began with "What Happens to This Shirt After I'm Done With It?"

ー Please tell us about Ambercycle's specific business operations.

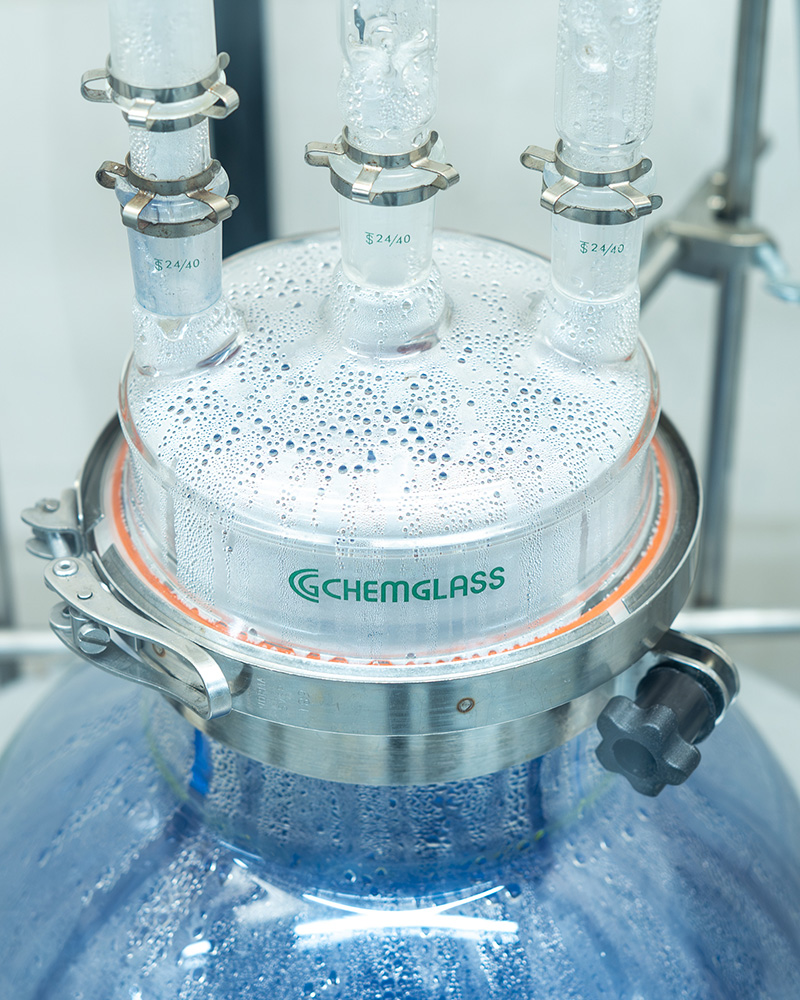

Shay: Our core innovation is called molecular regeneration. We collect end-of-life textiles and break them down at the molecular level. At this level, we can separate the different fibers by type and remove all the contaminants. We then purify that material into a new, high-quality input called cycora®, which can be used to make the highest quality brand-new garments.

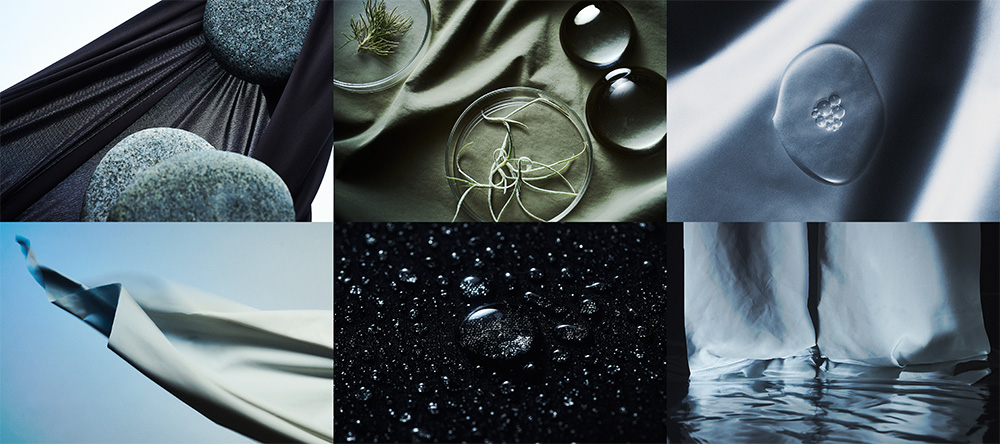

This method allows us to regenerate high-quality raw materials from waste while reducing dependence on fossil fuels. Moreover, cycora® is easily recyclable again. It's a system designed for continuous circulation.

ー When we talk about fibers, Ambercycle's cycora® is specifically recycled polyester, correct?

Shay: Yes, that's right. Polyester becomes extremely difficult to recycle once it's blended with other fibers or mixed with dyes and additives. Our molecular regeneration process can overcome that hurdle.

ー How does your recycling method differ from others? Could you explain what makes it superior?

Shay: cycora® products have been verified by the European Center for Innovative Textiles (a research institution for sustainable textile industry in France) as meeting the standards of brand-new products. We've also succeeded in dramatically reducing carbon dioxide emissions compared to new products. But the real value lies in the complete circular ecosystem.

ー What exactly do you mean by a circular ecosystem?

Shay: It's a system for collecting waste and delivering materials and products to our partners. We've redesigned that distribution from the ground up. This allows us to reduce environmental impact without sacrificing product quality. Also, when someone purchases a cycora® garment, it's designed to be part of a larger circular system, not just a shopping transaction.

ー I see.

Shay: Where this material came from, how it was designed, what happens when its life cycle ends—this transparency is very important and is a major reason why we started Ambercycle. When I was in college, I was looking for responsible ways to handle clothing. I always wondered, "What happens to this shirt after I'm done with it?" This system also addresses that question.

ー Could you share any challenges or memorable episodes you encountered while developing the material and building a new supply chain?

Shay: There were many difficulties because we were building something completely new from scratch, not just improving what already existed.

We spent five years conducting experiments with real textile waste to understand the chemical properties. The journey to integrate both the input and output of textile waste into the apparel supply chain was also a series of trials.

When we were trying to produce enough regenerated material to actually make clothing, it took months to stabilize the process. However, the sense of achievement when something previously impossible became possible was extraordinary. I believe challenges will continue, but I want to overcome them with our team.

ー What impact can the widespread adoption of Ambercycle's regenerated polyester have on society and the global environment?

Shay: Environmentally, it can significantly reduce dependence on petroleum-derived polyester. As a result, we can reduce carbon dioxide emissions, eliminate the need to consume new resources, and keep clothing away from landfills and incinerators.

Our vision is a world where materials circulate in a closed loop—where the shirt you wear today becomes the raw material for the shirt you'll wear tomorrow. Within this circularity, I believe consumers will develop a sense of "responsibility and participation." When they know their clothes can have a second life and that they can play a role in that process, the entire system begins to change. So what we're trying to do is not just bring about material change, but transform the entire system.

ー What challenges are you currently facing?

Shay: What we're focusing on most is scaling up. That means navigating everything from building large-scale facilities to adjusting supply chains and dealing with policies and regulations. We're not just producing materials; we're building an entirely new system for materials to move around the world. This requires time, capital, and cooperation across the entire value chain.

Another challenge is education, both within the industry and for consumers. Circularity is still a new concept for many people and requires a shift in thinking. We believe we need to increase awareness among brands, partners, and end users about what cycora® is and why it's important.

Aiming for a Future Where All Clothes in the World's Closets Are Made in a Circular Way.

ー Have you had any connections with Japan or Japanese companies so far?

Shay: I've had opportunities to work with several Japanese companies. Thanks to our collaborations with them, we've been able to showcase the quality and versatility of cycora®.

Japan is an important region for us, both commercially and philosophically. Their attention to detail, quality, and craftsmanship closely aligns with our approach to material innovation. Japan has the mindset and technology to maximize the potential of cycora®.

ー Currently, the Goldwin Play Earth Fund is investing in Ambercycle. Could you tell us how you met?

Shay: I had known about Goldwin for many years and truly admired their commitment to quality, design, and sustainability. Then, at one point, I was introduced by a close acquaintance, and everything just clicked. It was clear that we shared a common language of "impact" and "intentionality."

ー Could you also tell us about the process leading up to the investment decision?

Shay: First, we're very careful about the partners we allow to participate in our ecosystem. Alignment of values and commitment to creating lasting change are essential. We believe that deep partnerships are what bring about true transformation in the world around us. With Goldwin, we felt a strong resonance.

There was a clear alignment not only in our approach to products and innovation but also in the philosophy underlying what we're trying to build. After understanding their vision, I thought this wasn't just an investment but the beginning of a true collaboration. I'm grateful that we can build the future together.

ー How do you think Goldwin's manufacturing will evolve through the collaboration between the Goldwin Play Earth Fund and Ambercycle?

Shay: By combining Goldwin's expertise in design and performance with our molecular regeneration technology, I believe we can breathe life into the ecosystem and create circular materials and products at an entirely new level together. I think we can also rebuild the entire manufacturing process.

Ultimately, I believe this collaboration will redefine the future of textiles, not only from a sustainability perspective but also in terms of how consumers experience products. I hope we can open doors for Goldwin users to connect more deeply with what they wear, enjoy new adventures, and build longer, more meaningful relationships with their items.

ー Finally, could you tell us about the future that Ambercycle aims for?

Shay: We aim for a world where all clothing in closets worldwide is made in a circular way. This means building the infrastructure, materials, and mindset needed to completely eliminate waste from the system. If we can build such a future, clothing will have no end but will continue in an ongoing lifecycle.

Since our founding, we've been dedicated to pushing the boundaries of what's possible, not just in chemistry but from sourcing materials to regeneration and returning them to the economy. And we will continue to push forward. To truly transform this industry, we need to redesign it from the ground up, centering on environmental impact, product excellence, and circularity.

Text_Keisuke Kimura

Edit_Shuhei Wakiyama(HOUYHNHNM / Rhino inc.)