Goldwin Play Earth Fund PORTFOLIO INTRODUCTION

Vol.5Colorifix

Revolutionizing the dyeing industry with the power of microorganisms.

ー Please tell us about how you two co-founders first met.

Jim: We first met in 2012. It all started when I hired Orr into my laboratory to work on biosensors for water quality research. At that time, I had gained some recognition in the field of synthetic biology, including advising the Cambridge University team that won the 2009 iGEM (The International Genetically Engineered Machine competition). I was also responsible for managing biological safety at Cambridge University's Department of Pathology.

Orr: As a postdoctoral researcher joining Jim's laboratory, I helped develop biosensors for use in South Asia, drawing on my past research experience at Cambridge University and the University of Edinburgh. When we visited stakeholders affected by large-scale water pollution, Jim and I witnessed firsthand the serious impact that textile products have on the global environment and how much pollution the dyeing process causes. That's when we thought of trying a new approach using microorganisms to colour materials, and that became the beginning of "Colorifix."

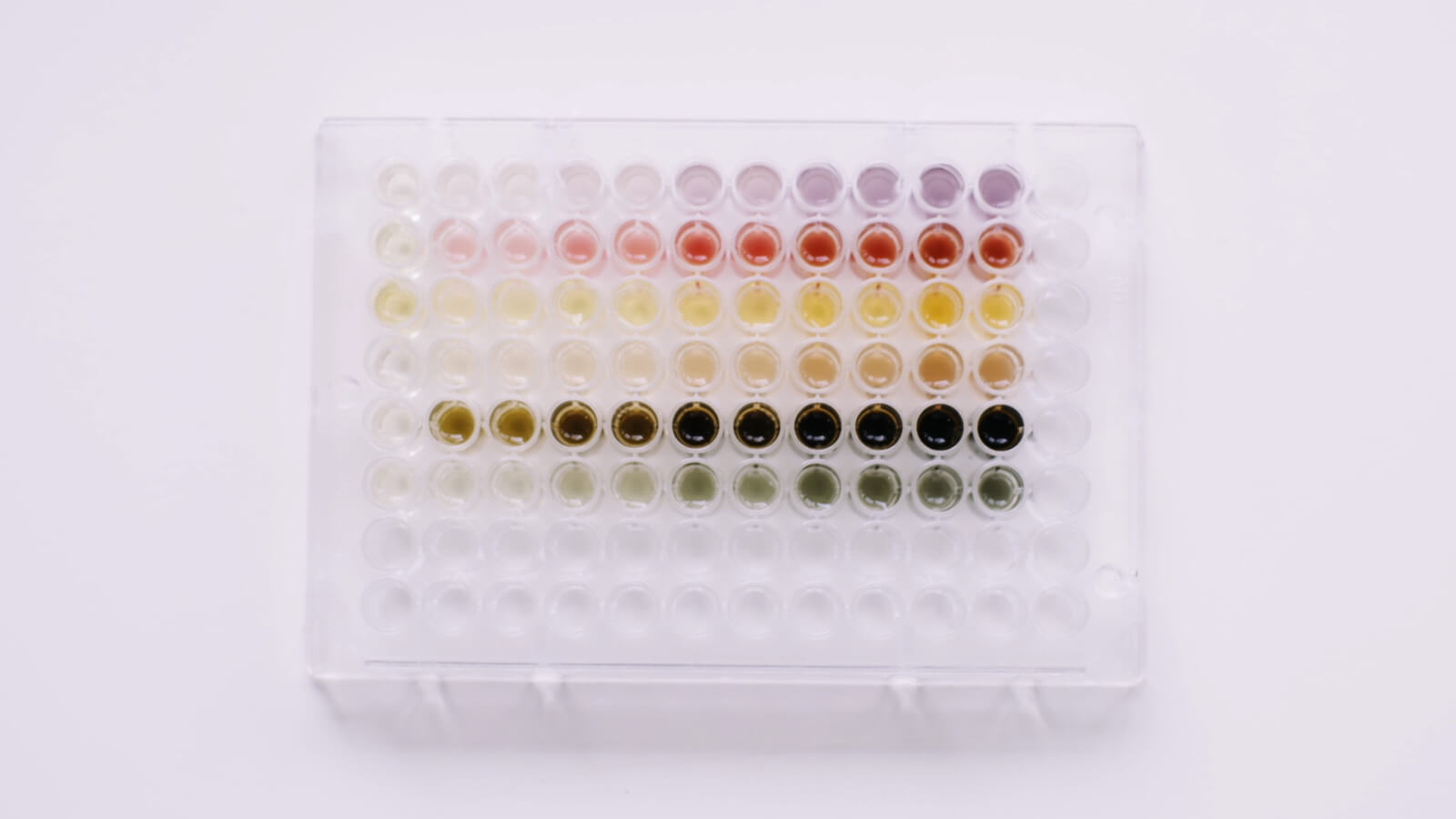

Various colours are created using bacteria.

ー Please tell us about your specific business activities.

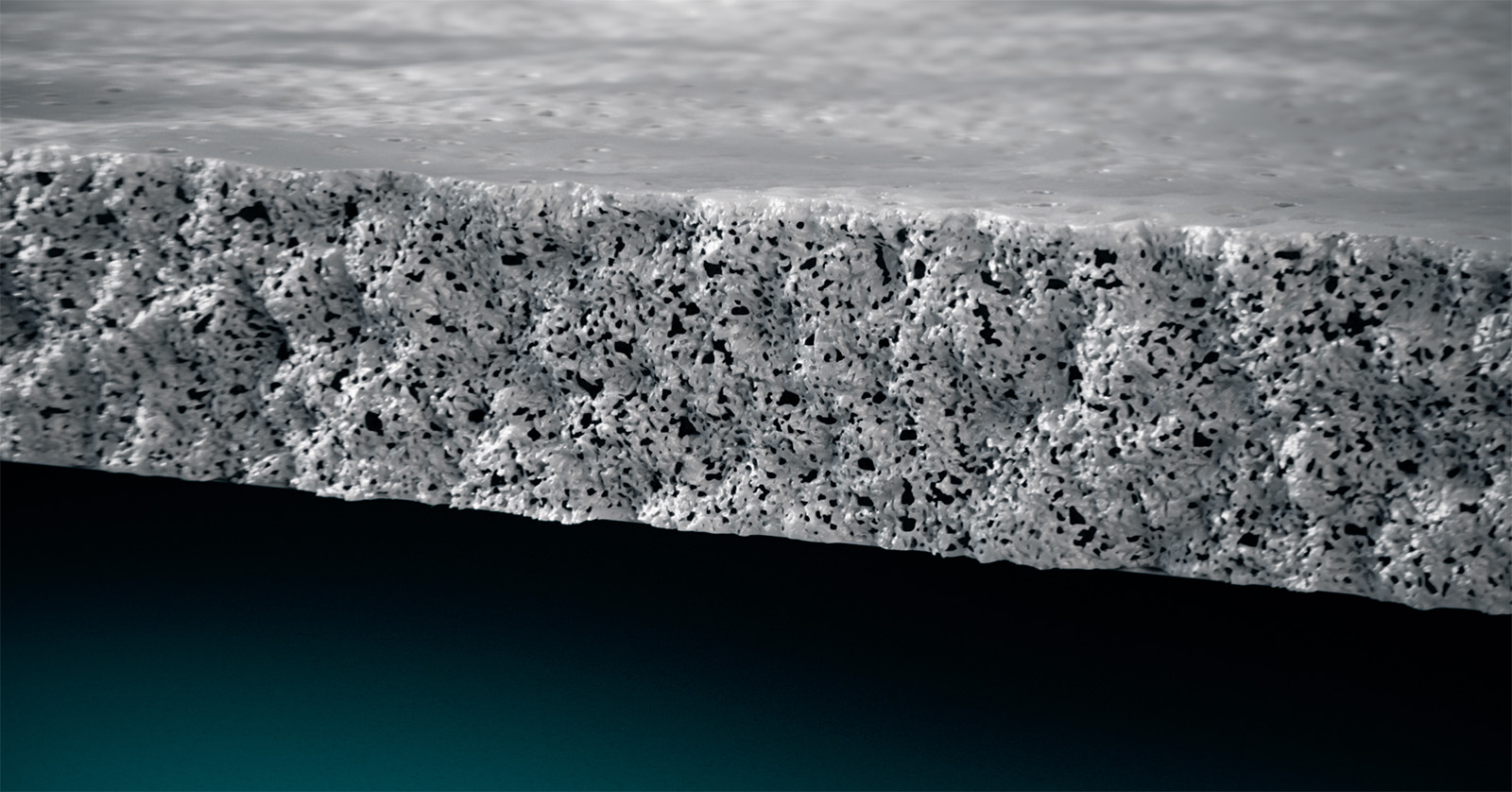

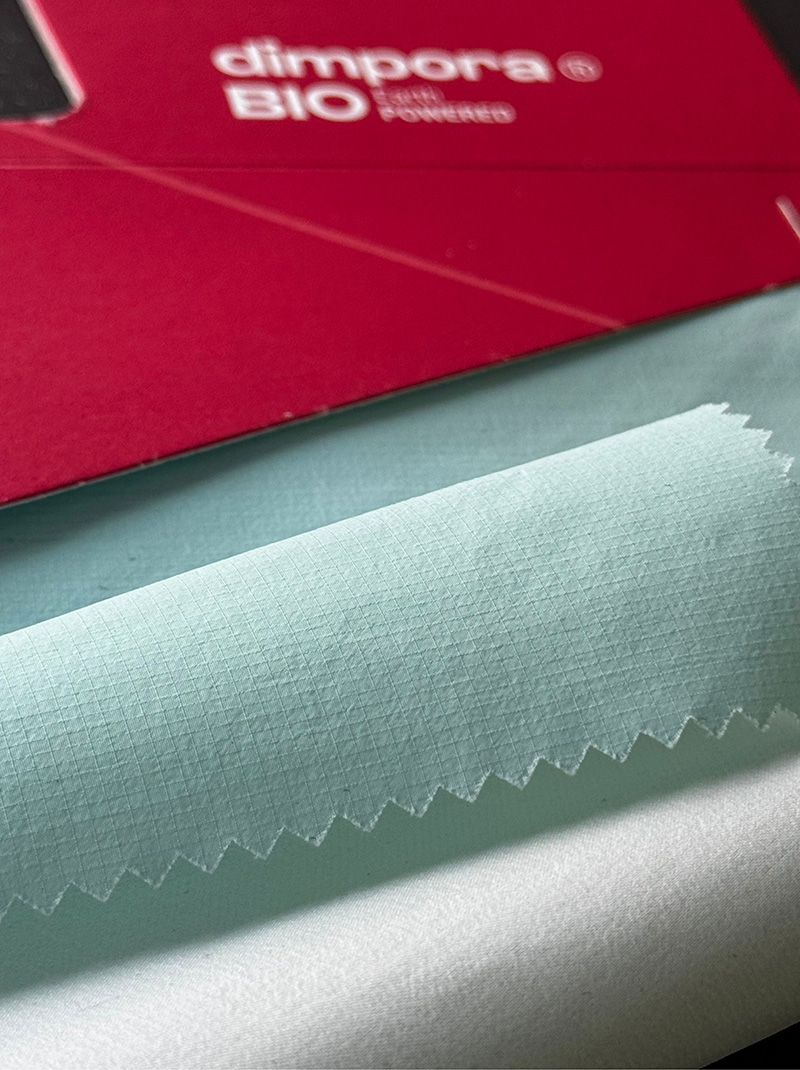

Orr: Colorifix was created to bring real biotechnology to the textile wet processing sector. We developed an end-to-end process of how to make, deposit and fix colour onto fabrics using engineered microbes. These make the same colours you see anywhere in nature, like plants, insects, mammals or even other microscopic creatures; at scale using sugar, nitrogen and salt as the only inputs - just the way Nature does it. It’s what we like to call “life friendly” chemistry.

Jim: Not only are we displacing all the petrochemical production impact of making colour, we are actually saving a lot in the process of applying the colour to fabric. We save on water, energy and emissions at every stage of the process and we are really proud to bring performance comparable to the synthetic dyes we are displacing at competitive pricing and minimal environmental impact.

ー What is the scale of Colorifix as a company?

Jim: Colorifix has around 85 employees, across three countries. Our headquarters in Norwich, UK is where most of the R&D takes place - where new colours are developed, tested and validated. In Portugal we have our production team assemble the hardware needed to make the process integrate easily in the dyehouse and our customer implementation team works from there to help dyehouses switch to our biological process.

Orr: In India, where we are just starting, our small team is setting up towards servicing the Indian market with print paste and dye liquor as early as this year.The atmosphere is one of purpose and energy, with many things happening at the same time. Our focus is on scaling and increasing the amount of fabric dyed per week using biology and our efforts are starting to pay off.

ー Which brands have adopted "Colorifix" dyes or collaborated with you so far?

Jim: H&M was the first brand to launch a T-shirt dyed with our technology in the Colour Story collection in 2021, followed by a capsule collection with Pangaia. Panagia launched a pair of track pants and a matching hoodie in two different colours, pink and blue, that all sold out within 3 hours. Our most recent launch was Vollebak, developing a range of men’s T-shirts, sweaters, hoodies and shorts.

Unique colours born from extreme environments.

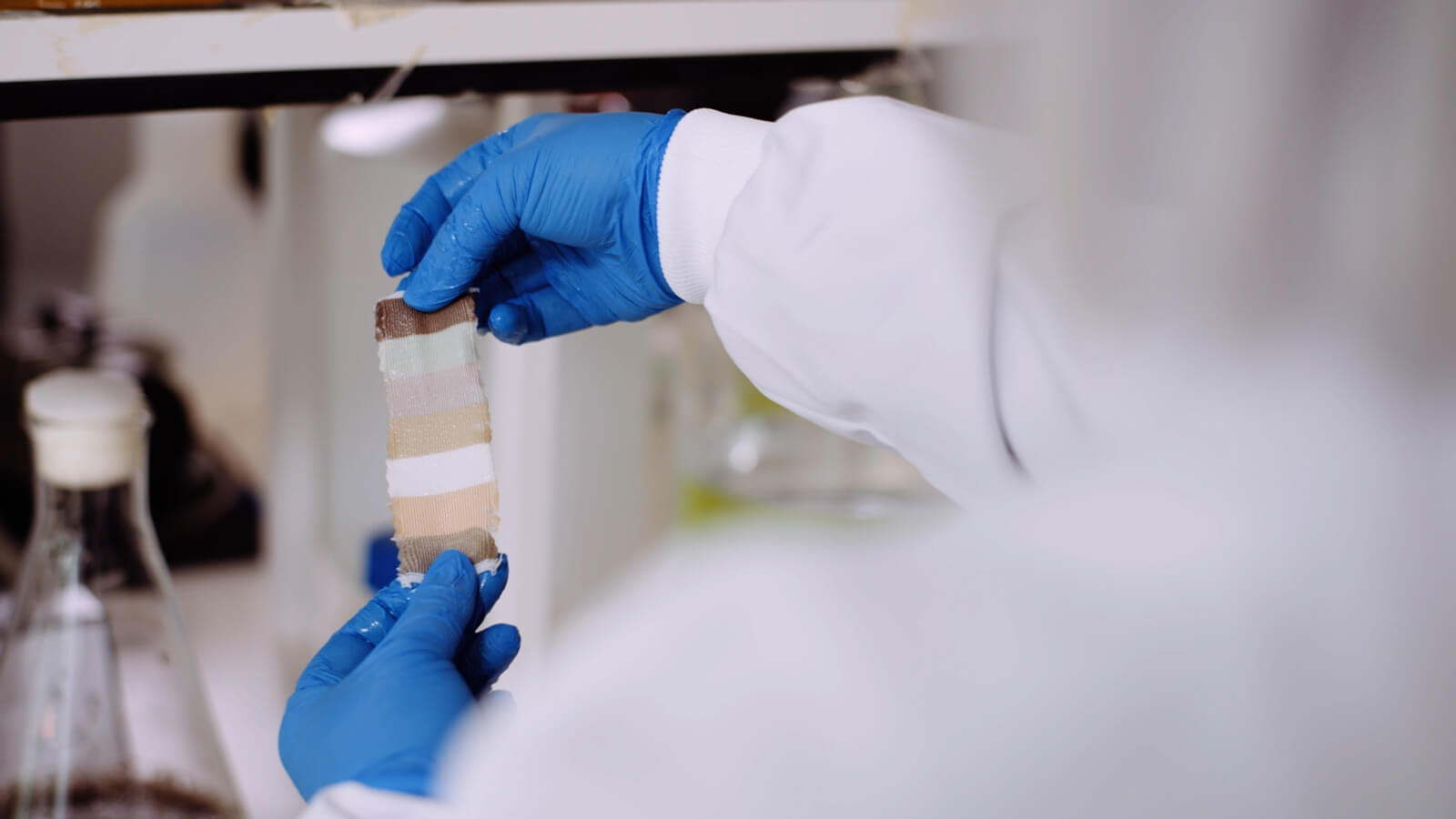

ー "Colorifix" has attractive and unique colour tones. How are colours selected and dyes developed?

Orr: The pigments have remarkable origin stories. The pink Blushing Rose was first produced by ancient bacteria that thrive in extreme conditions, such as in and around geysers; and our blue Oceanic Tide is a bacterium found in mineral-rich waters.

Jim: However, nature can make the same pigment in many places, and we don’t always borrow the DNA code from the original source. Once we have identified a pigment of interest, we search online databases for an organism that makes that pigment in the most efficient way; and we use that DNA code as the template for engineering our microbes.

ー Please tell us about the process from bacteria to dyes and then to actual dyeing.

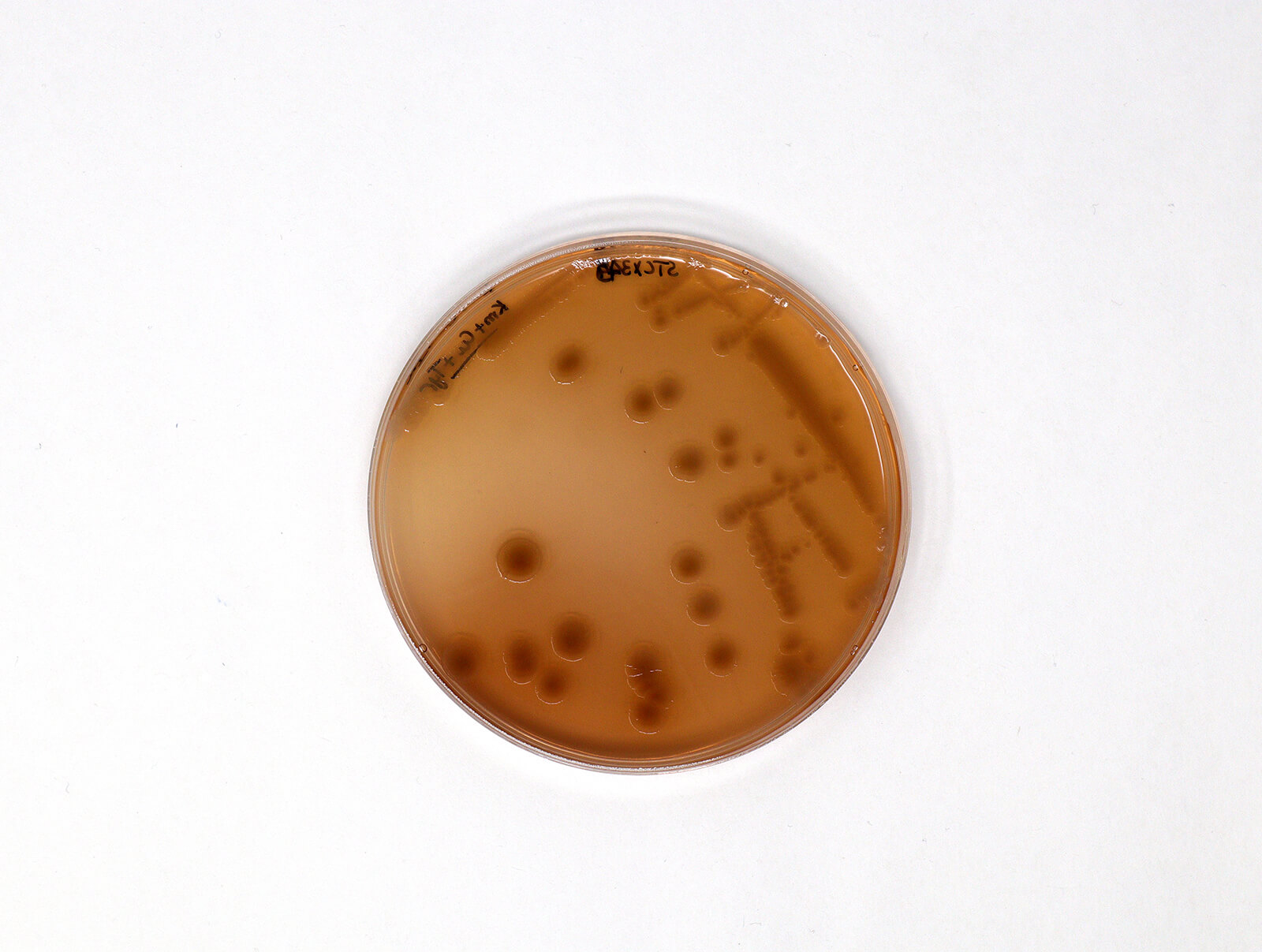

Jim: First, Colorifix identifies an organism—be it a plant, animal, insect, or microbe—that produces an interesting colour. Instead of using a physical specimen, they rely on online databases to examine the organism’s DNA and pinpoint the exact genes responsible for producing that colour.

Orr: Once they have identified the genes, they synthesise the DNA and insert it into a safe microbe, which could be a bacteria or yeast. This engineered microbe then acts as a tiny biological factory, producing the desired colour. The microbes are cultivated in a fermentor, much like brewing beer. They grow on non-hazardous ingredients that could include agricultural by-products naturally rich in sugars, peptides, and salts. These ingredients provide the necessary nutrients for the microbes to thrive and produce the pigment.

Jim: After the fermentation process is complete, everything in the fermentor—the microbes, water and media (microbial food) —is pumped into standard dye machines with the fabric. The microbes attach the pigment to the material, achieving the desired colour. This process not only eliminates the need for harmful chemicals but also utilises renewable feedstocks instead of petroleum, making it a low-impact alternative to traditional dyeing methods.

53% reduction in power consumption, 31% in CO2 emissions, 77% in water consumption.

ー How long did it take to develop the technology using bacteria as a pigment source? Also, please tell us about the challenges you faced.

Jim: It took only a couple of years to prove the principle and raise awareness and funding. It took nearly a decade to get to the point of industrial scale and real impact. The major challenges were in scaling and finding an integration solution for applying biology where chemistry is the norm. Making hardware that is market leading, simple to operate and efficient to run in a dyehouse was not a simple challenge.

ー Water usage and wastewater during dyeing are serious problems in the apparel industry. How much can resource usage be reduced by using "Colorifix" dyes compared to conventional synthetic dyes?

Orr: With our technology, we eliminate the use of any harmful substances throughout the dyeing process but we want to go beyond that. That’s why we measure our overall environmental impact from the process to monitor and improve it at every stage. Our latest Life Cycle Analysis (LCA), comparing the conventional dyeing process to the Colorifix process, included two stages: dyeing and final washes, performed on 1 Kg of knit jersey 52% recycled cotton 48% recycled polyester. The results in the dyeing step showed that at least 53% less electricity was used, savings of at least 31% in CO2 emissions and 77% less water consumed.

ー Please tell us about what you're currently working on and what you'd like to tackle next.

Jim: First, optimizing pigment yield: We're working to improve pigment yield and potency (a concentration measurement method in biology), particularly for polyester three-colour pigments. This will enable us to reduce production costs. We've also developed three individual products (yellow, blue, pink) that can be used for colour mixing. This expands the spectrum of colours our customers can create.

Orr: We're also continuing to scale up at customer sites to meet orders from various brands, and to make ourselves known to more people, we've launched "Colorifix Studio," which provides fabrics dyed with Colorifix to brands, designers, and innovators to create collections.

Jim: Within the next few years, we also aim to use our waste in agriculture, turning textile dyeing pollution into quality fertilizer.

ー While the importance of environmental issues and sustainability awareness is being proclaimed worldwide, in Japan there's an impression that words are getting ahead of action. What are your thoughts on this?

Jim: I think Japan leads the world in environmental protection at the individual level. This is evident from the fact that every street is clean despite having virtually no public trash cans.

Orr: Japan's unique practice of sorting household waste also raises awareness of how much damage humans are causing to the planet. From waste cleanup to forest planting, we believe these activities not only raise environmental awareness but also build strong communities.

Social impact through collaboration with global brands.

ー Have you had any connections with Japan before?

Jim: I have Japanese heritage, and my surname is Ajioka. The Ajioka family has served as guards for the Emperor for generations, so I still cherish the Emperor's thoughts and feelings following my ancestors. That's why I'm happy to work more directly in Japan.

ー Please tell us about the process leading to the investment decision by GOLDWIN PLAY EARTH FUND.

Orr: It was in 2023. The Goldwin team came to the UK, where we had many conversations and discovered that our thoughts aligned with their mission. From there, they made valuable proposals about how to grow the business in the next phase through new partners and investors.

ー What does Colorifix hope to achieve through collaboration with Goldwin? Also, what positive impact do you think this collaboration will have on society?

Jim: In order for Colorifix to maximise its positive societal impact, we need to build partnerships with established international brands that can help to deliver our technology to consumers across the globe. Goldwin is a perfect example of this and indeed we are excited that the brand is looking to increase its presence in the UK. We trust that there will be lots of opportunities for collaboration in the future.

ー Please also tell us about your future vision.

Jim: We want to continue increasing the number and type of biological products we release and continue replacing petrochemistry and polluting practices wherever possible. This includes paper, plastics, building materials and one day even food and makeup. These are our next steps, but the reality is that colour is only the beginning, we will be putting other types of function into all of those materials over time.

Text_Keisuke Kimura

Edit_Shuhei Wakiyama(HOUYHNHNM / Rhino inc.)