Goldwin Play Earth Fund PORTFOLIO INTRODUCTION

Vol.4Dimpora AG

Swiss start-up Dimpora AG

— Could you start by introducing yourself?

Mario:My name is Mario Stucki, I’m a chemical engineer by training and currently the CEO and co-founder of Dimpora AG. I studied chemical and bioengineering at ETH Zurich, where I also completed my PhD.

— I understand that you began researching sustainable membranes when you were a student.

Mario:It was during my time at ETH that I started working on sustainable alternatives to conventional waterproof membranes, first as a master’s project and then as part of my doctoral research.

— So that research has led you to your current business.

Mario:Exactly. During my master’s studies, I developed a breathable, fluorine-free membrane for rain jackets. Recognizing the potential of this technology to address environmental concerns in outdoor apparel, I continued refining it throughout my doctoral research. In 2019, together with my colleague Anna Beltzung, we co-founded Dimpora AG to bring this sustainable membrane technology to market.

— Could you tell us about Dimpora AG’s mission?

Mario:We’re here to prove that high performance and sustainability can go hand in hand. We develop membranes that are free of toxic chemicals and designed with circularity in mind. Our goal is simple: to help outdoor brands create gear that protects people and the planet. This commitment ensures that outdoor enthusiasts can enjoy nature without leaving a detrimental impact on the environment.

— Have you always had a passion for outdoor activities?

Mario:Yes, absolutely! I’ve always had a passion for the outdoors. I grew up in Switzerland, where being in nature is part of everyday life. Hiking, skiing, and fishing are not just hobbies for me but ways to stay connected to the environment we’re trying to protect through our work. That personal connection to the outdoors is a big part of why I’m so committed to what we do and why Dimpora was born.

Resolve the contradiction of Loving nature but wearing something that harms it.

— What led you to develop a PFC-free microporous membrane?

Mario:I was already very interested in sustainability, and as someone who loves the outdoors, I started questioning what went into the clothes we wear when we’re out in nature. That’s when I realized that most high-performance outdoor gear relies on membranes made with fluorinated chemicals, PFCs or PFAS, that don’t degrade in nature and accumulate in the environment and our bodies. That felt like a contradiction: loving nature but wearing something that harms it.

— Were there any particularly memorable moments leading up to the launch?

Mario:Some key moments stand out for me, like seeing our first scaled production run come off the machine and getting the first serious interest from international brands. That’s when it became clear this wasn’t just a concept; it was something the industry needed.

— Why did you choose to focus on waterproof and breathable textiles and membranes?

Mario:I focused on membranes because they are invisible but absolutely critical. They’re what make the difference between comfort and misery out there. But they’re often overlooked, and unfortunately, many are made with harmful materials. That’s where I saw a big opportunity: to create something better, something that performs just as well but is kinder to the environment.That combination of technical challenge, environmental urgency, and love for the outdoors made it an “easy” decision to dive into membranes. It’s a niche, but one with the power to create meaningful impact.

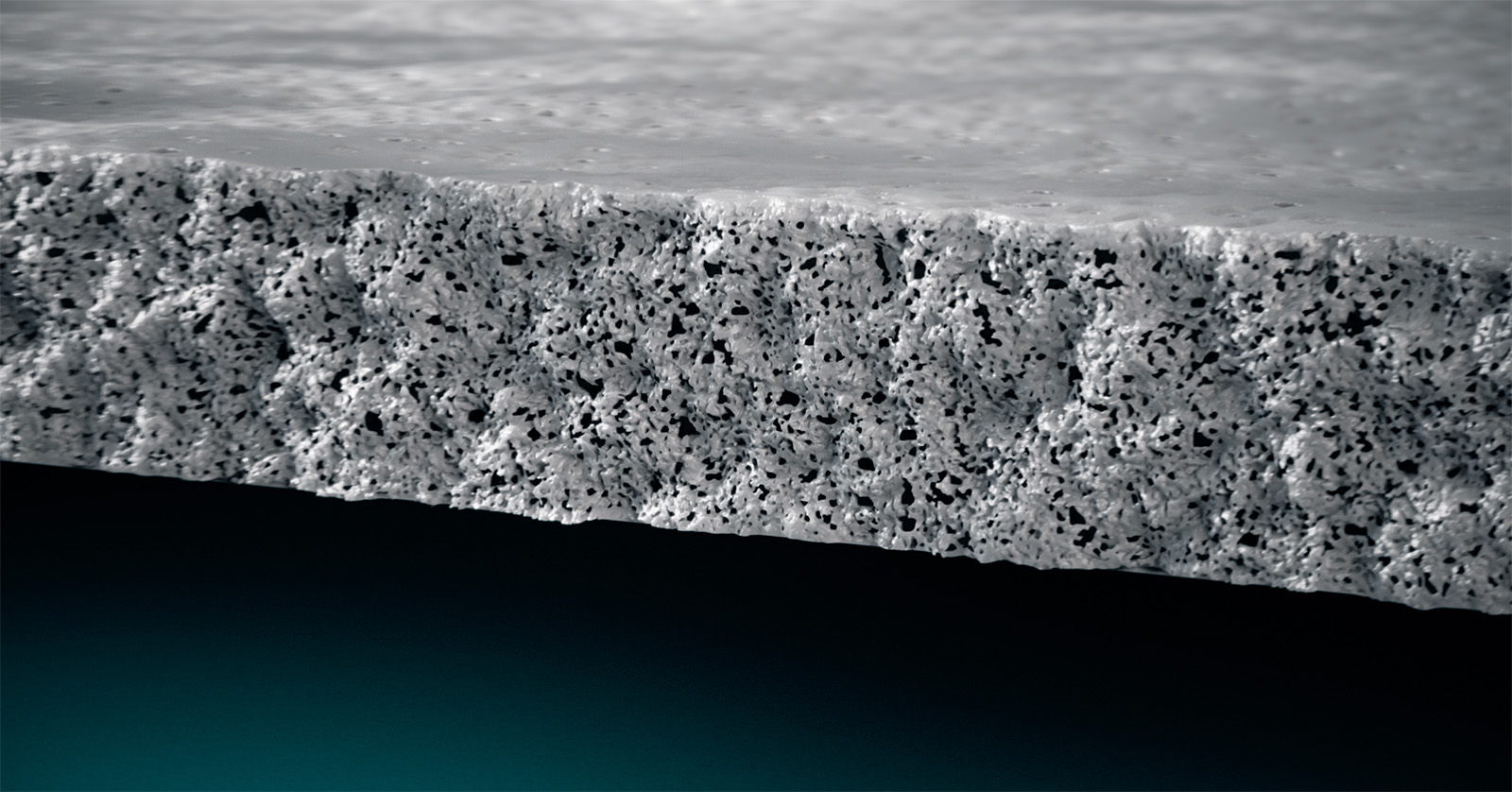

— What are the characteristics of Dimpora AG’s membranes?

Mario:All our membranes are built using our patented CoreLayer Technology, which is really the backbone of everything we do. It allows us to work with any polymer, which is unique in the industry, and gives us the flexibility to tailor performance levels: from highly breathable to extremely waterproof, or anywhere in between. And importantly, our technology allows us to achieve all this without using toxic solvents a key factor in how we’ve managed to cut CO₂ emissions by 92%. It’s a milestone we’re proud of, and one that makes a real difference not just for the planet, but also for the brands we work with, helping them move closer to their own sustainability goals.

— What is your current product lineup and what is different about each?

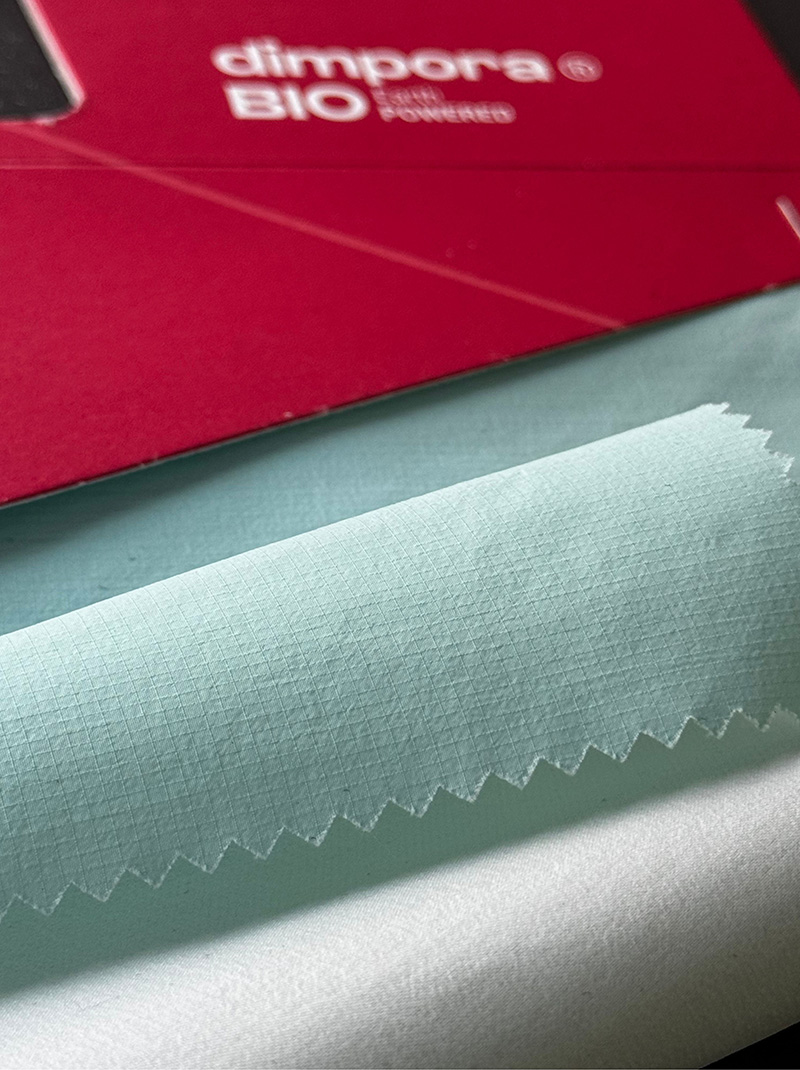

Mario:As for our current products include dimpora®, dimpora®BIO, and dimpora®MONO. dimpora® is our original and most waterproof solution, made from polypropylene.dimpora® BIO is the first microporous membrane with over 60% biobased content on the market. It’s derived from castor oil and comes with multiple performance options, so brands can choose based on their needs.dimpora® MONO is our monomaterial series. Designed specifically to be laminated with fabrics of the same polymer family, enabling easier mechanical recycling at the end of a garment’s life. It’s ideal for circular design and increasingly in demand among brands looking to simplify end-of-life.

— Are there any new products or innovations currently in development?

Mario:Yes, two exciting ones. First, we’re working on dimpora® BIO MONO, which we believe is a major breakthrough for the industry. It’s the first bio-based, monomaterial membrane laminate of its kind. It combines high performance with over 60% biobased content, and because the membrane and fabric are from the same polymer family, it’s designed for true circularity. Meaning it can be recycled without separating the different materials.

— What is the other one?

Mario:We’re also developing dimpora® 3D, a fluid version of our membrane that can be sprayed or coated directly onto textiles. This eliminates the need for seams, glue, and multiple layers, removing weak points and reducing waste. It opens up completely new design possibilities, and we’re actively looking for partners to co-develop the technology.

Pioneering a new world with like-minded companies

— In addition to Goldwin Play Earth Fund, are there any other companies that have invested in Dimpora AG? If there were specific criteria for choosing investors, please let us know.

Mario:Yes, we do have other investors on board, and we’re really happy with the group we’ve assembled. They’ve been incredibly supportive and bring a great mix of experience and perspective. We feel fortunate to have a strong and balanced cap table at this stage. That said, we’re still looking for partners who can complement our network, reach, and skill set. Strategic alignment is key for us, and we’re always open to collaborators who can bring more than just capital, ideally, people who can help us accelerate growth and expand our impact.

— Could you share the process leading up to Goldwin Play Earth Fund’s investment? Were there any particularly memorable moments along the way?

Mario:We were initially introduced to Goldwin as a potential customer to collaborate on developing premium clothing. As we got to know each other better, the conversation naturally evolved into something more, eventually leading to discussions about investment. What really stood out to us was how deeply aligned we were, not just on product vision and quality, but also on long-term thinking and values when it comes to building a business. We met several times and had really thoughtful conversations over a period of time. It wasn’t rushed—it felt like a mutual understanding growing step by step.

— Are there aspects of Goldwin’s business or philosophy that resonate with you?

Mario:Definitely. Goldwin’s philosophy of harmonizing with nature aligns with our mission. We also admire the focus on functional design and their dedication to material innovation. There’s a shared commitment to pushing boundaries in a thoughtful, sustainable way, which makes their approach very inspiring to us.

— What kind of synergy do you think Dimpora AG and Goldwin can create together?

Mario:Together, we can create products that not only perform exceptionally but also set a new standard for sustainability in the outdoor industry. This collaboration has the potential to show that high-performance and environmental responsibility don’t have to be at odds. If we can inspire both the industry and end consumers to expect more, from both materials and brands, we’re already making a positive impact.

— Lastly, could you share Dimpora AG’s vision for the future?

Mario:Our vision is to redefine what performance means in the textile industry, where sustainability isn’t a compromise but a given. As an ingredient brand, we want to empower outdoor brands to create high-performance products that leave no harmful trace, from the materials they choose to how garments are made and eventually disposed of. In the long run, we’re building a platform technology that adapts to different needs, industries, and sustainability goals but is always grounded in science, transparency, and real impact. And by enabling better materials from the inside out, we aim to inspire end consumers to expect more from what they wear. Our hope is that one day, the most advanced gear in the world will also be the most sustainable.

Text_Keisuke Kimura

Edit_Shuhei Wakiyama(HOUYHNHNM / Rhino inc.)